What are non-tactile membrane switches?

To understand non-tactile membrane switches, it’s first important to examine how membrane switches work as a whole.

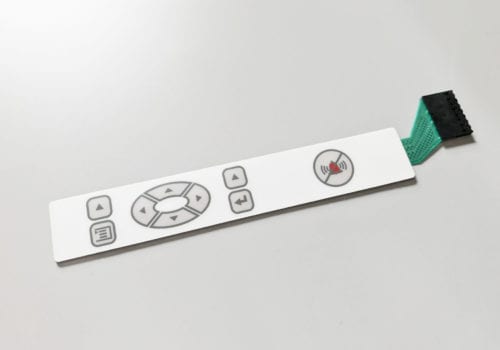

- Membrane switches are comprised of several different layers, including:

- The graphics overlay

- Adhesive layers

- The circuit layer (generally a flexible printed circuit printed circuit board)

The function of a membrane switch is to provide a user interface onto which graphics like icons, instructions, and logos can be easily printed. When a user presses a button, the switch is activated, and the user receives feedback.

The sleek, thin profile of the membrane switch means it can be incorporated into any number of electronic devices. The membrane switch fits seamlessly into the final product, drastically reducing the risk of contamination.

All user interfaces must provide feedback to users—membrane switches are no exception. The core difference between a tactile and non-tactile membrane switch is in how they provide feedback when a switch is activated:

Tactile switches offer a tactile response—users can feel when the switch is activated

Non-tactile switches must offer other forms of feedback—usually auditory and visual feedback

At first glance, it may seem like a tactile membrane switch is the best option, given that they offer an extra form of feedback. The tactile vs. non-tactile switch dichotomy is not quite so simple, however. There are many advantages to non-tactile switches.

Membrane Switch Terminology Guide

Pros and cons of non-tactile membrane switches

To understand the pros of a non-tactile switch, we’ll examine the advantages of membrane switches as a whole. A membrane switch offers:

- A sleek profile

- Excellent ingress protection (up to IP67)

- A graphics layer for logos, icons, instructions, and more

- High resistance to contaminants

- Compatibility with a variety of coatings

- Compatibility with a number of features, including backlighting

- And much more

Our membrane switches offer a high level of customizability. When you choose a non-tactile switch, the level of customizability is at its highest. Compared to a tactile membrane switch, the non-tactile version has:

- A sleeker profile

- A longer lifespan – up to 2 million actuations

- The option for no noise when the switch is activated (there’s no clicking or popping)

- Higher resistance to contamination

- Lower overall cost

All of these are excellent reasons to choose a membrane switch without tactile feedback.

Membrane switches can be built with a number of features, including:

- Backlighting

- Shielding

- Windows

- Anti-UV and other coatings

- A variety of finishes (gloss, anti-glare, etc.)

- And more

By omitting tactile feedback, your membrane switch may become more cost-effective. This can leave more room in your budget for other desirable features.

The disadvantage of these membrane switches is obvious when compared to their tactile cousins. Tactile feedback is essential in some industries where immediate, tangible feedback is necessary for safety. There are also times when other forms of feedback may be distracting, annoying, or even dangerous (typically in healthcare applications).

When you should use a non-tactile membrane switch

A non-tactile user interface is generally a good idea when:

- Auditory and visual feedback are sufficient (many consumer electronics)

- You’re trying to make your final product more cost-effective

- You expect your final product to be interfaced with very frequently

- You want to avoid the noise that tactile switches can emit

This makes a standard membrane switch without metal domes for tactility an excellent option across a variety of industries, including:

- Consumer electronics

- Transportation

- Medical devices

- And more

Get in touch with General Label for non-tactile membrane switches

We design, engineer, and manufacture custom membrane switches for our clients. Whether you’re looking for a switch with metal domes for physical feedback or for one with other forms of sensory feedback, we can help.

Our membrane switches are long-lasting, durable, fully customizable, and built to fit perfectly with your final product’s specifications. Get in touch with us today.