3M™ Preferred Converter

What Is a Material Converter?

A material converter is a company that combines and modifies a variety of raw materials to make products. These raw materials are supplied to the converter in the form of webs or sheets of materials. These materials are then fed through processing machines.

There’s almost no limit to the different materials that can be converted – or to the different processes that can be used to convert materials. We convert a wide variety of different raw materials, including:

- Polyesters

- Polyimide (Kapton)

- Polycarbonates

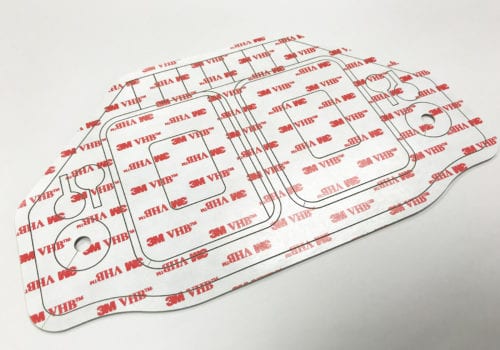

- Adhesives

- Silicone

- Adhesive tapes

- Acoustical meshes

- Foams

- Plastics

- Felts

- Rubbers

- Liners

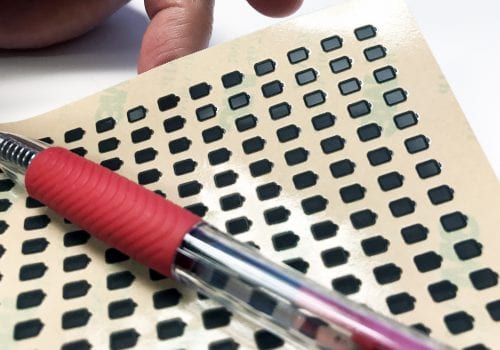

- Conductive inks

- And more

These materials can be combined together to create all manner of different products, from gaskets to overlays with EMI shielding. Our experience in material converting means we can make almost any design come to life. If you can dream it, we can build it.

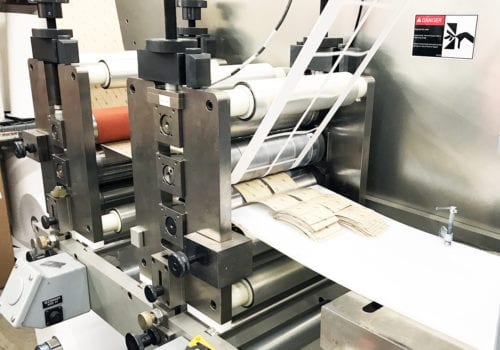

We’ve optimized our supply chain to obtain raw materials at extremely competitive rates. But the materials a company works with are only one-half of the equation. A great material converter needs machinery capable of manipulating materials, and engineers who know exactly what manipulations are required. Fortunately, General Label has both. Some of the machines we use include:

- Printing presses

- Laminating machines

- Slitting machines

- Laser cutting machines

- Tangent knife systems

- Rotary die cutting machines

- Rotary laser cutting machines

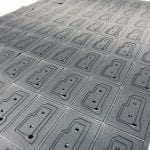

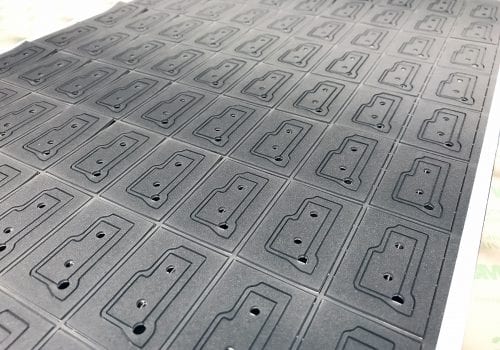

Our laser cutting machine was custom-built, allowing us to make a variety of different cuts, including thru cut, kiss-cut, combo cut, ablation, and more. And our web converting and finishing machines can operate in tandem, reducing costs, improving the speed at which the final product can be manufactured, and improving quality.

We Can Help Develop, Prototype, and Scale for Production

We’re a full-service materials converter. That means we offer:

- Design support and engineering

- Manufacturing

- Quality assurance

General Label can handle every element of the material converting process, from conceptualizing your product to manufacturing it at scale. Some of the products and parts we’ve helped manufacture include:

- Gaskets and vibration dampening

- Optically clear adhesives

- Bonding and joining

- EMI shielding

- Surface protection films

- High-temperature die-cut and laser-cut masks for plating

- Acoustic mesh with adhesive borders

- And more

Our engineers are here to ensure that our final products can meet even the most exacting tolerances. Our sophisticated machinery means we can die-cut or laser-cut materials into extremely complex shapes with exacting precision. With the wide array of materials and techniques we have available, we can imbue your final product or part with many useful properties, including:

- Acoustic dampening (or heightening)

- Antimicrobial

- Temperature resistance (heat and cold)

- Abrasion resistance

- Explosion resistance

- Reflectivity

- UV resistance

- Custom colors

- Custom shapes

- Custom perforations

- EMI shielding

- And much more

The list goes on and on – with a custom materials converter like General Label on your side, there’s almost no limit to the kinds of products and parts you can make. We work with distributors, OEMs, and more. The industries we serve include:

- Industrial

- Electronic

- Automotive

- Medical

- Agriculture

- Appliance

- Consumer

- Property/Asset

- OEM

- Transportation

- Aerospace

- Contract manufacturing

- Oil and Gas

- IoT Solutions

Whatever your material converting needs are, whatever industry you’re a part of, General Label can help you improve your products and parts. Our material converting capacities are second to none. We’ve been serving North America for over 30 years. Our state-of-the-art technology and expert techniques mean we can create almost anything you could imagine. Our incredible relationship with suppliers means we can offer extremely competitive rates.

For projects large or small, contact us today.