OEMs and other manufacturers are constantly looking for new ways of improving the user interface (UI) of their devices. Great UIs for physical devices have a lot in common. They should be:

- Intuitive

- Responsive

- Durable

- Long-lasting

- Cost Effective

- Easy to incorporate into your product

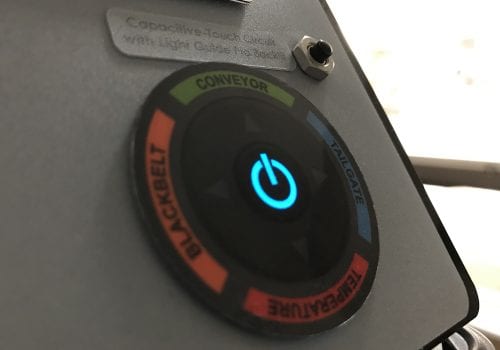

Capacitive switch touchscreens offer all of the above—and more. Users have come to expect the types of feedback that these touchscreens provide—they’re used in vehicles, on kitchen appliances, medical devices, and more. Let’s explore what capacitive switch touchscreens are, how they work, and their many advantages.

What is a capacitive switch touchscreen?

Capacitive membranes—or capacitive touchscreens—are touch-sensitive switches with no mechanical components. They’re made up of three layers:

- The graphic overlay

- The capacitive circuit

- The adhesive layer

Our touchscreens are incredibly thin—a mere 0.06 inches / 1.5 mm in thickness. They’re also flexible, and while typically used on flat surfaces, This allows manufacturers to create touch-sensitive UIs on products where traditional mechanical switches might not be feasible.

Responsiveness is a key component of any successful UI. Mechanical switches provide responsiveness through tactility—users can feel that they’ve pressed a button. Capacitive switches provide responsiveness through visuals—buttons light up (or go dark) based on user input. We can incorporate other responsive features, like audible noises through the board level of the part. .

Our backlit membrane switches, utilizing top fired and/or side fired LEDs – as small at 08/05 – allows your users to easily intuit that they’ve activated a function—all while providing an incredibly sleek, 1.5 mm UI.

With no mechanical parts and strong adhesives, capacitive switch touchscreens are incredibly long-lasting and durable. Our switches can be built to high IP standards such as water-resistance at (IP67) and can last for the lifespan of your device.

How does a capacitive touch sensor work?

Sensor

The technology underpinning capacitive switch touchscreens is deceptively simple: Sensors that measure a change in capacitance (the ability of a material object or device to store electric charge). Air has a certain capacitance—so does the human finger.

When a finger replaces the air within a sensor’s field, the sensor detects the change in capacitance, and it triggers an event, such as an LED turning on or interaction with the controller (like turning on the device in question).

Most capacitive switch touchscreens will have multiple sensors—one for each button on the screen. These sensors are coupled with connection tails, often made out of polyester or Kapton.

Many early iterations of capacitive switch touchscreens used printed circuit boards (PCB) in order to sense changes in capacitance and trigger events. Today, flexible printed circuits (FPC) are another option, allowing for the type of flexibility discussed above.

Controller

The capacitive switch touchscreen will be affixed to your device’s controller through the use of an adhesive, we can incorporate a 3M VHB Gasket for extreme sealing in environments exposed to water, dust, and other contaminants.. This seals the screen to the controller. Laminating your touchscreen with EMI shielding protects your device’s controller and provides a sleek interface.

Our capacitive switch touch screens are tested individually (never batch-tested). They’re also manufactured specifically for use on your device. This makes it easy to affix the screen to your controller—simply remove the backing, line it up with your device’s controller, then press down to affix it.

All capacitive touch screens and membrane switches are assembled in an ISO Class 7 Clean Room Environment to ensure quality parts for the end UI controlling your device.

Trust General Label for capacitive switch touchscreens

With decades of experience creating capacitive switches for many different industries, we know what it takes to make a great user interface. Get in touch with General Label today.